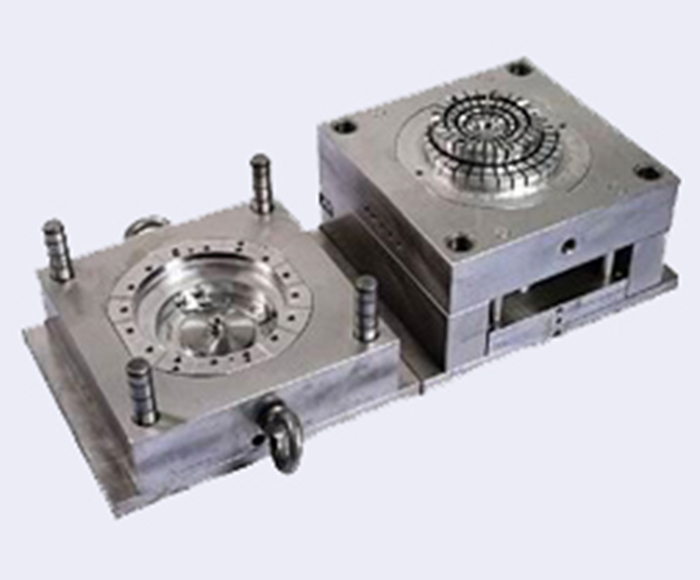

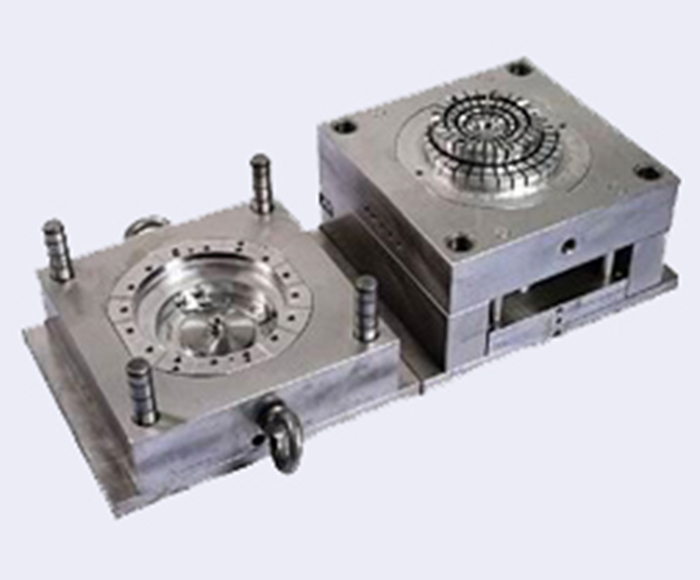

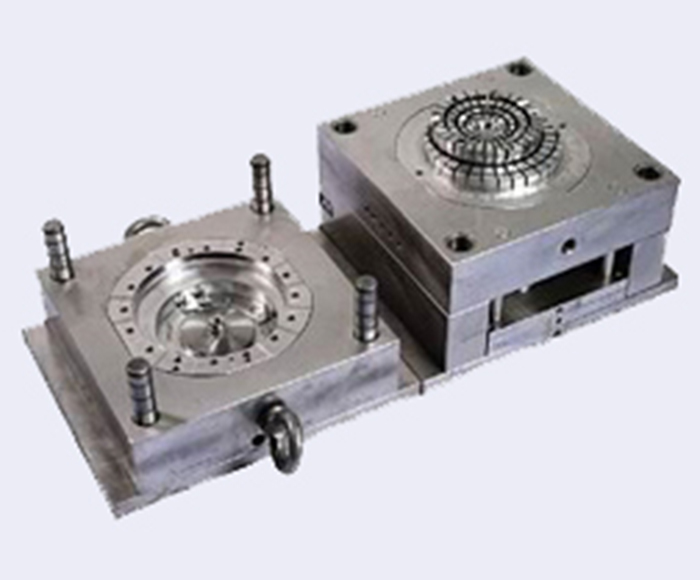

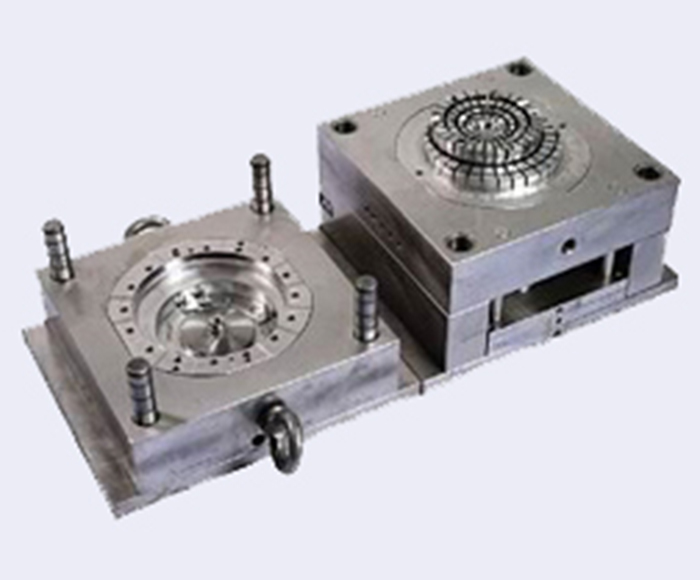

automobile Injection mould It is a kind of mold for producing automotive plastic products. This mold must have complete structure and accurate size. It is a kind of mold with strong practicability.

Processing technology

The heated melted materials are fed into the mold cavity under certain high pressure, so that the molded parts of the automobile injection mold are obtained after certain cooling treatment.

This is a kind of combined plastic mold, which is mainly composed of intaglio composite substrate, and can be processed into automobile injection molds of different shapes and sizes according to the specific needs of users.

market demand

Now, with the development of economy and the improvement of people's living standards, cars have entered every household. As a very important equipment for the production of cars, auto injection molds must now be in great demand. Therefore, the quality of automobile injection mold must be strictly controlled to meet the market demand.

Injection mold is a method of industrial product production modeling. Products are usually injected with rubber and plastic. Injection molding can also be divided into injection molding and die-casting.

Injection molding machine (injection machine or injection molding machine for short) is the main molding equipment that uses plastic molding molds to make thermoplastic or thermosetting materials into plastic products of various shapes. Injection molding is realized through injection molding machines and molds.

1. Rubber injection molding: rubber injection molding is a production method that directly injects rubber from the barrel into the mold for vulcanization. The advantages of rubber injection molding are: although it is intermittent operation, the molding cycle is short, the production efficiency is high, the embryo preparation process is canceled, the labor intensity is small, and the product quality is excellent.

2. Plastic injection molding: plastic injection molding is a method of plastic products. Molten plastic is injected into the plastic product mold by pressure, and then cooled to form various desired plastic parts. There are mechanical injection molding machines specially used for injection molding. Polystyrene is the most commonly used plastic at present.

3. Injection molding: The shape obtained is often a finished product, and no other processing is required before installation or use as a finished product. Many details, such as bulges, ribs and threads, can be molded in one step of injection molding.

Purpose, operation and results of temperature, pressure, speed and cooling control

● How the adjustment of injection molding machine setting affects the process and quality

● Optimize screw control settings

● Multi section filling and multi section pressure maintaining control; Effect of Crystallization, Amorphous and Molecular/Fiber Orientation on Process and Quality

● Influence of internal stress, cooling rate and plastic shrinkage on the quality of plastic parts

● Rheology of plastics: how plastics flow, flow direction and change viscosity, shear and molecular/fiber flow direction

● Relationship between gating system, cooling system, mold structure and injection molding process