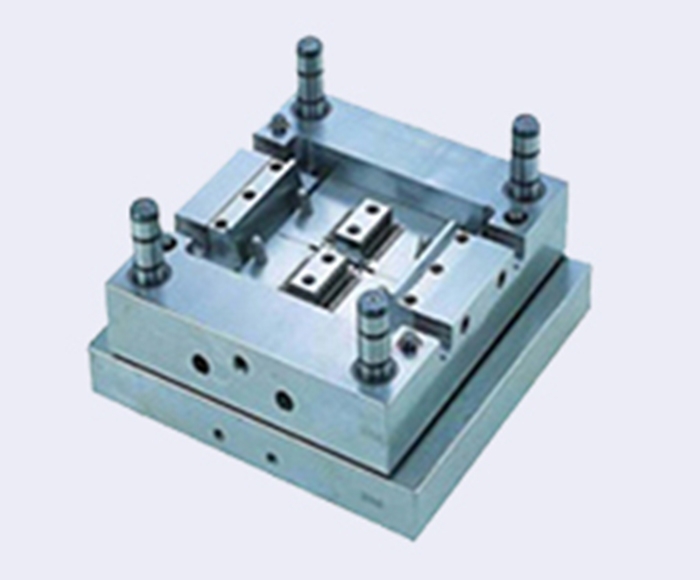

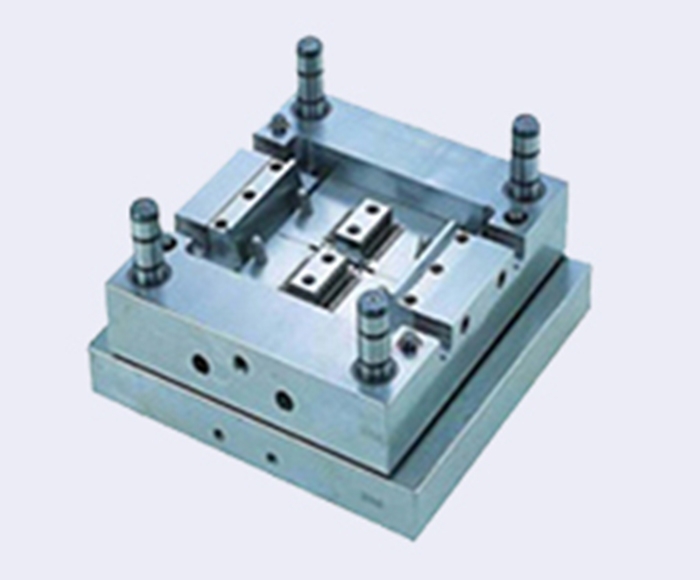

Injection mold processing plant How to improve the quality of mould during processing

Injection mould Manufacturing is a very complex process. From the initial design, processing, assembly, debugging and other steps to the actual use later, in the entire life cycle, the impact of each process on the quality of injection mold must be taken into account, and every detail must be in place, so as to improve the quality of the later injection mold.

1. The quality of casting materials directly affects the quality of injection molds. It is very important to select materials with good performance and heat resistance. In this way, the products produced are good.

2. The design of injection mold should be scientific and reasonable. For technical researchers, if they want to design things to meet the current market demand, they must design reasonably, use standard mold structure, and complete the standard implementation of the advantages and disadvantages of mold parts, the usability of mold structure, and technical processability.

3. Perfect quenching process is indispensable for injection mold. The quenching steps should be operated correctly. If a step is misoperated, it will cause quality problems in the produced mold, resulting in the inability to use the injection mold or shortening the service life.

4. Mold assembly: injection mold assembly is just like the assembly machine. Each part and each screw must not be wrong, otherwise the consequences will be quite serious, ranging from product defects to affect production, to complete damage to the mold and scrap. So the assembly work must be very meticulous. In the process of assembly, especially pay attention to the cleaning of the mold, especially the waterway and screw holes. Be sure to blow out the iron filings inside.

5. Mold maintenance: Mold maintenance mainly refers to the maintenance during production. Every time the mold is used, comprehensive maintenance shall be carried out, especially the rust prevention of the forming part and the rust prevention of the main moving parts. Because the mold needs to be connected with water during production, it may fall asleep on the mold during installation or disassembly, so make sure that the mold is dry, and then brush a layer of oil for protection.