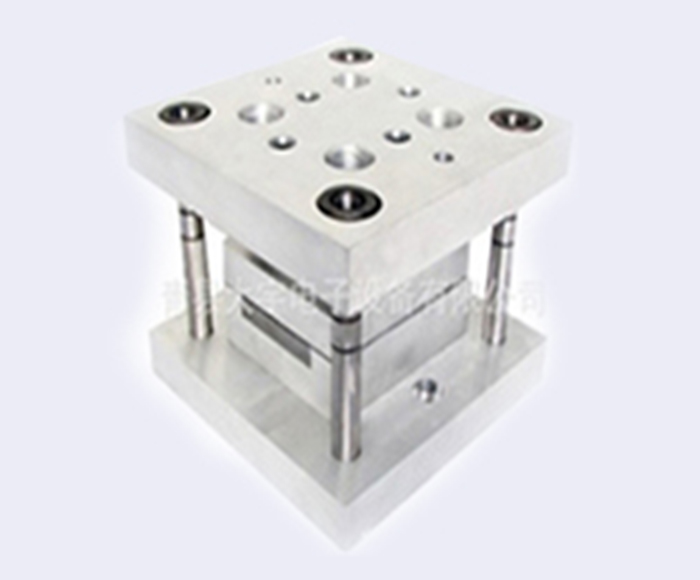

Injection mould It is a special type of mold, mainly including transmission mold, blow molding mold and injection mold, Injection mold for battery box It is also a kind of injection mold.

constitute

It is mainly composed of a gating system and a temperature regulating system, and has high requirements on the smoothness and accuracy of the overall mold. Now this injection mold is widely used in our production.

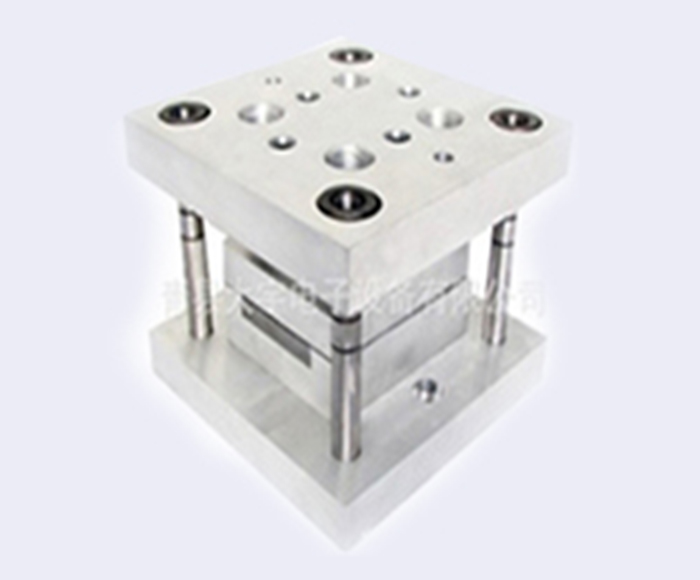

Advantages - extremely practical

1. The service life is very strong. Generally, the injection mold of the battery box can be used normally for more than 500000 mold times.

2. It has extremely strong hardness and wear resistance.

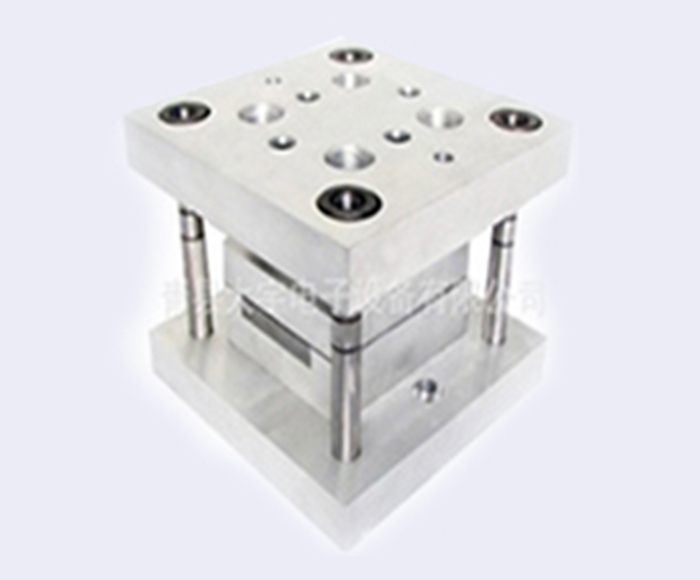

Precautions for maintenance

1. First of all, the processing enterprise should be equipped with a resume card, so that the use of the entire mold and its subsequent care can be recorded in detail.

2. Secondly, the processing enterprise needs to test the performance of the mold before using the battery box injection mold, and judge the possible damage of the mold in the later stage according to the information characteristics of the battery box injection mold.

3. We should attach great importance to the surface maintenance of the injection mold for the battery box, and protect the rust prevention of the mold, so as to ensure the later use of the injection mold for the battery box.

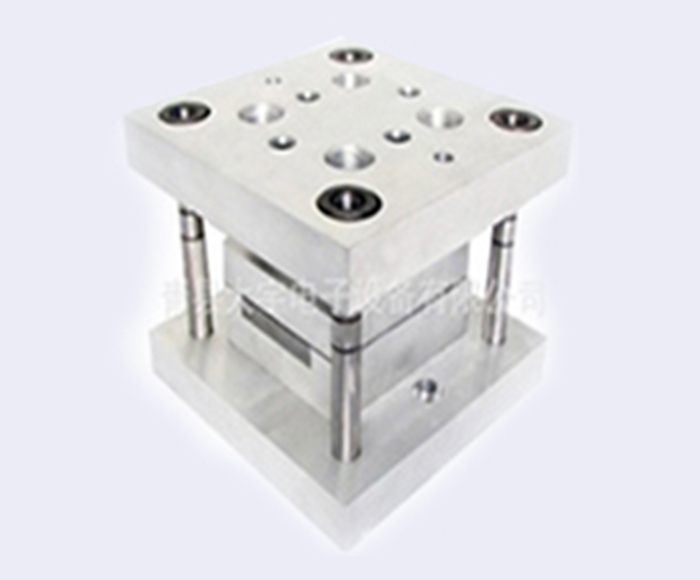

In our production and life, molds have been widely used, such as various extrusion molds Electrical plastic injection mold The use of these molds makes our production more convenient.

Main manufacturing materials

ABS, PVC and HIPS.

advantage

1. It can guarantee the use quality of electrical appliances very well

2. It can greatly extend the electrical service life

3. The manufacturing of electrical plastic injection mold includes a cooling system, which can optimize the design of circulating water flow, greatly improve production efficiency, and greatly reduce production costs.

Matters needing attention in the middle and later stage treatment

1. The hardness of the mold should be improved during the intermediate treatment, and the electrical plastic injection mold should be quenched and tempered.

2. The mold should be nitrided in the post treatment. These treatments make the overall temperature of the mold very low, and there is no need for quenching.